The phenomenon of the electromagnetic induction heating is based on three physical principles, here below explained:

-

Transfer of energy from the inductor to the piece to be heated, by means of Electromagnetic Fields.

-

Transformation of the electric energy into heat due to Joule effect. (P=I2R)

-

Transmission of the heat inside the mass by means of Thermal Conduction.

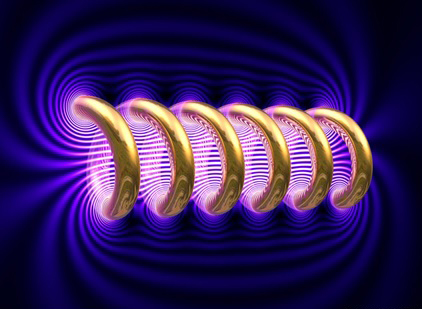

The electro-magnetic field is generated by the current flowing on the coil.

If the coil has got a solenoid shape, the intensity of the electro-magnetic field is proportional to the number of loops of the coil as well.

A workpiece that is placed inside or nearby the heating coil, are induced parasitic current, also called eddy currents.

According to the Laplace Law, the intensity of the magnetic field is reverse proportional to the square of the distance from the coil.

According to Faraday-Lenz’s Law, the induced current generated on the workpiece is proportional to the rate of change of the magnet flux (Frequency).

Eddy currents are currents induced in conductors, opposing the change in flux that generated them. They are caused when a conductor is exposed to a changing magnetic field.

These circulating eddy current create induced magnetic fields that oppose the change of the original magnetic field due to Lenz’ laws, causing repulsive or drag forces between the conductor and the coil.

The stronger the applied magnetic field, or the greater the electrical conductivity of the conductor, or the faster the field that the conductor is exposed to changes, then the greater the currents that are developed.

The energy induced on the workpiece to be heated is therefore a function of:

- Current intensity on the coil

- Operating frequency

- Coil shape and distance to the workpiece

- Workpiece magnetic permeability and resistivity (influenced by target temperature and Curie Temperature for magnetic items)