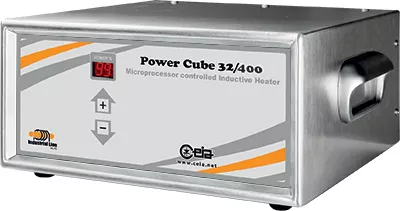

Power Cube Series 400 Generators

High Frequency Generators

High Frequency Generators

| Power Cube 32/400 | Power Cube 45/400 | ||

| Power Supply and Power | Input current | 13A max - external conductors ø2.5 min. | 16A max - external conductors ø4 min. |

| Average power at inductor | 32 kVAR | 45 kVAR | |

| Maximum absorbed power | 2.8 kW | 3.5 kW | |

| Supply voltage | 180 ÷ 260 Vac, monophase - 50/60 Hz | ||

| Frequency Range | 375 kHz... 575 kHz | ||

| Cooling | Water cooling | Pressure: 300 kPa | |

| Water flow for each connected head | From 1.5 to 2 l/min | ||

| Control Inputs | RS232 serial interface | 1 RS232 asynchronous serial port for connection with external PLC or Controller | |

| Digital input activator | 2 isolated digital inputs for the cycle activation switches | ||

| Analogue power adjustment input | 2 analog inputs for output power control (optional) | ||

| Operating Conditions | Operating temperature | + 5 °C to + 55 °C | |

| Storage temperature | - 25 °C to + 70 °C | ||

| Relative humidity | 20-95% (without condensation) | ||

| Dimensions (WxDxH) | Generator | 275 mm x 265 mm x 140 mm | 275 mm x 265 mm x 140 mm |

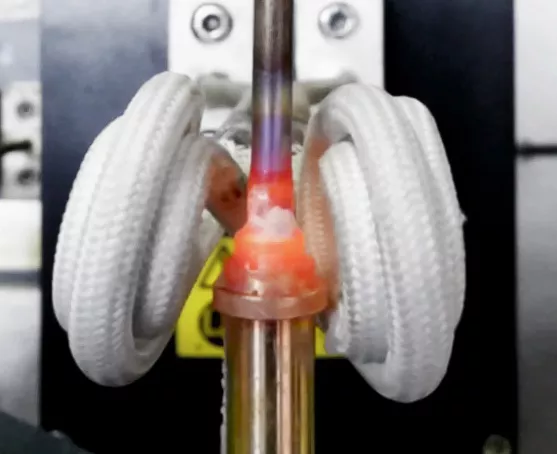

| Heating head HH10/HH11 | 62,5 mm x 123 mm x 95 mmm | 62,5 mm x 123 mm x 95 mm | |

| Miniaturized heating head HH15 | 52 mm x 107 mm x 77 mm | 52 mm x 107 mm x 77 mm | |

| Standard inductor holder | 150 mm | 150 mm | |

| Weight | Generator | 10 kg | 10 kg |

| Heating head | 2 kg | 2 kg | |

| Conformity | Complies with international standards currently applicable for Electrical Safety (EN 60204-1, EN 60519-1, EN 60519-3) and Electromagnetic Compatibility (EN 55011, EN 61000-6-2) | ||

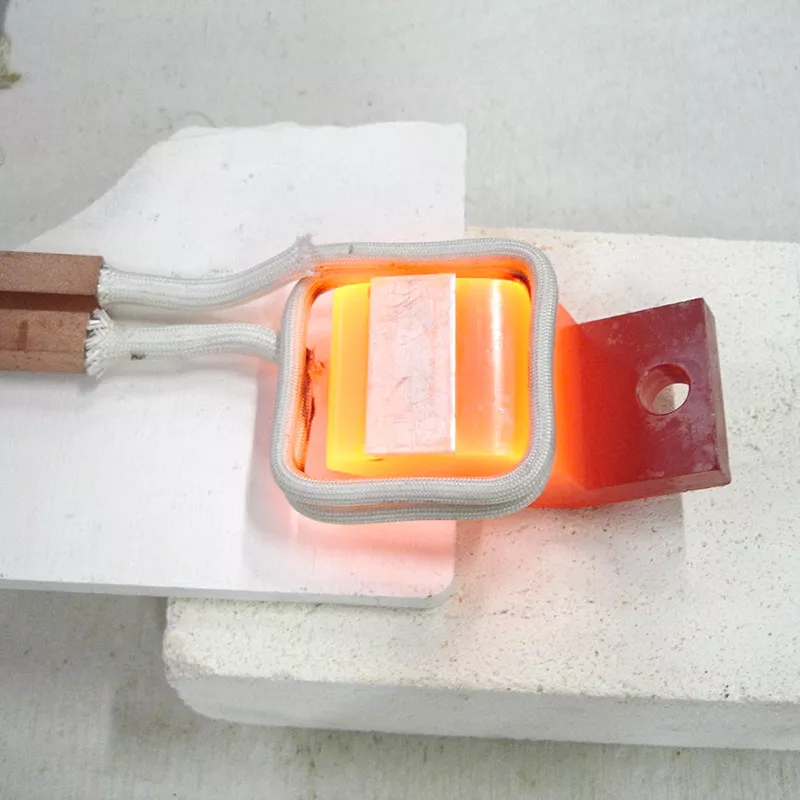

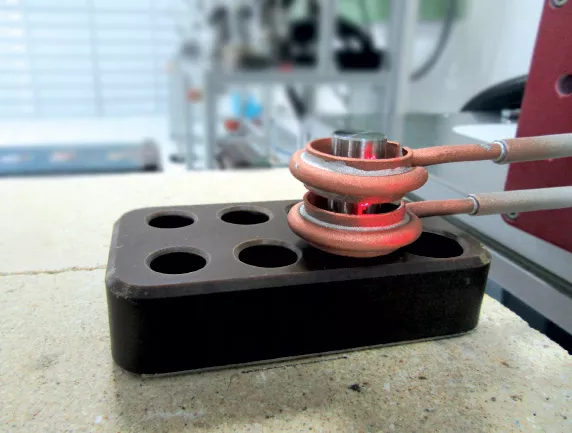

For more than 40 years CEIA has been working on the design and manufacture of no-contact Induction Heating Devices for metal treatment. High and medium-frequency generators, control units, optical sensors for measuring temperature and automatic solder-alloy wire supply devices make up the line of products known as the Power Cube Family, which are ideal for industrial processes of heat treatment and braze welding.

CEIA's unique technological solutions allow the manufacturing of power equipment with compact size, extremely high-energy efficiency and long-term reliability.

The high performance they offer contributes to the widespread use of CEIA systems in the most important industrial fields, where they have received the approval of end users and final-product manufacturers.